Professional Powder Coating Machine COLO-191S-V

Features

1. COLO-191S powder coating machine is widely used for any shapes of workpieces thanks to the powerful technologies.

2. The box feed unit allows easy and frequent color changes with the direct powder conveying from the powder box.

3. The combination of digital smart controller and 100kV powder spray gun ensures great performance.

4. The smooth and uniform powder flow creates an even powder coating film on the parts, and ensures sufficient coating coverage in depressions.

5. Offering innovative technologies to achieve the ideal charging of even challenging powders like structured and metallic powders.

Details

Controller

- With DVC (digital valve control) technology provides flexibility and precision to set and adjust all parameters, such as voltage, amperage, airflow, powder output.

- One-touch buttons and the easy-to-use interface make this coating machine easily operated for everyone.

- There are 3 pre-set application programs for processing flat parts, profiles and recoating jobs. This function makes it easy-to-use for beginners.

- Additionally, 20 individual coating programmed can be stored and retrieved at any time. This achieves repeatable and outstanding coating results.

Powder Spray Gun

- Built-in 100kV cascade maximizes the electrostatic charging, offering the highest transfer efficiency.

- Made of lightweight materials with ergonomic shape that avoids operator fatigue.

- Robust powder spray gun design decreases the failure rate and prolongs service life.

- Remote control of changing powder flow and application programs on the back cover, fast and easy.

Spray Nozzles

- Equipped with full sizes of nozzle assortments, prepare for spraying various workpieces.

- Round and flat nozzles are suitable for most common workpieces, extension nozzles for inside powder coating of narrow areas.

Powder Pump

- Delivers more powders to spray guns using less compressed air, achieving efficient material utilization and lowered consumption costs.

- A plug-in powder injector that can be detached without any tool, allowing fast cleaning and maintenance.

Trolley

- A vibrating motor in the trolley fluidizes the powder, breaks up powder accumulation, removes absorbed moisture, greatly improving powder coating quality.

- The movable trolley makes the powder coating machine easy to transport within the production area.

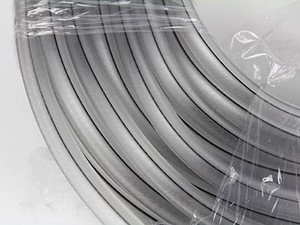

Grounded Powder Hose

- The grounded powder hose embedded with carbon strips features anti-static, ensuring constant and uniform flow.

- This powder hose is easy and quick to clean during color change process.